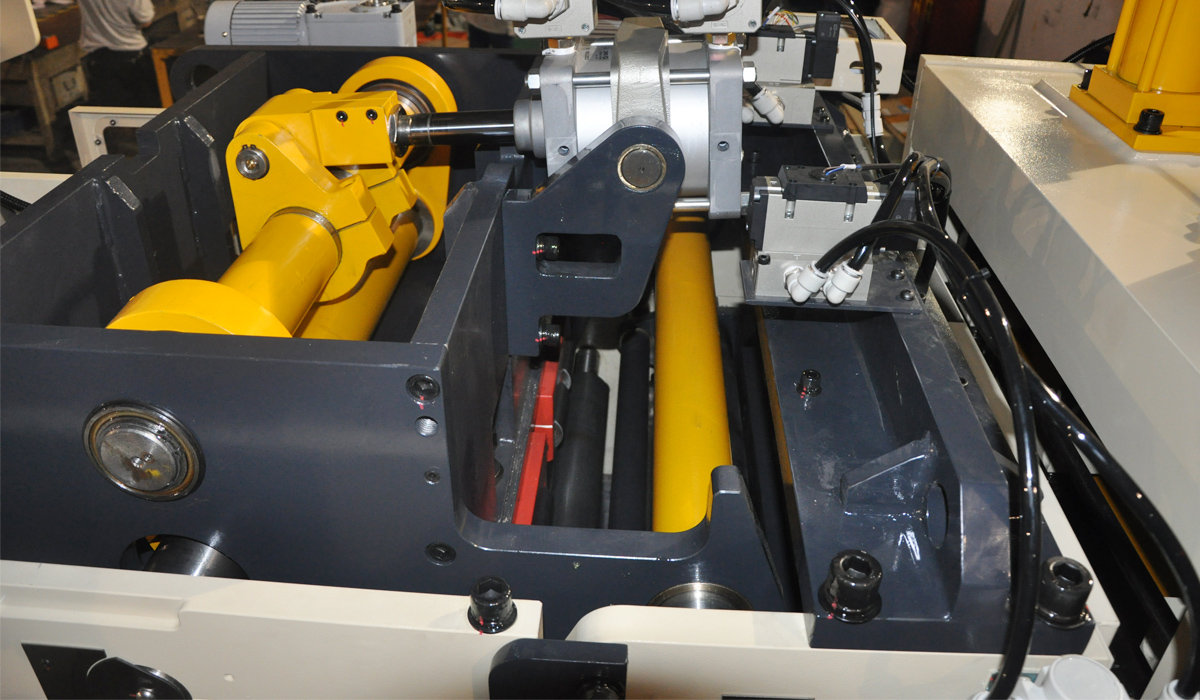

Quality inspection during production

Process inspection is often a link that is easily overlooked by the manufacturing industry, but it directly affects production efficiency and product quality.

Chance move's quality control team has quality engineers who are specifically responsible for process inspection. Itinerant inspections ensure that production and assembly are carried out according to standard processes.